close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

| Layer | 2L-20L |

| Base Material | Copper |

| Specification | PCB customized size |

| Delivery | 7-14 Days |

| Certification | UL(CUL), IS09001&IS014001, IATF16949, REACH, RoHS, |

| Application | EV charging station |

| Transport Package | Vacuum Package and Foam Protected |

| Copper thickness | 2-40oz |

| Surface treatment | OSP, HASL, Tin, Immersion Gold (Au), Immersion Silver (Ag), ENIG, ENPIG |

| Min. Trace/Space | 3.5mil / 3.5mil |

| Dielectric Layer Thermal Conductivity(w/m.k) | 380.0W-400.0W, Breakdown Voltage: 2KV - 6KV |

| Current Loading | 200A+ single line capacity |

Our Reliable Material Suppliers

Our Product Features

1.Thermal Management. Afford IGBT overheating at 400V/800V.Superior Heat Dissipation.Direct thermal path from components to the copper block, reducing junction temperature by 30%.

2.Space Constraint. Integrate power and control logic on a single board

3.Reliability. Work well under extreme outdoor temperatures

4.High Current Handling: Heavy copper combined with embedded blocks to minimize losses.

5.Space Saving. Eliminates the need for bulky external busbars and heavy heatsinks.

6.Extreme Durability: Tested for thermal cycles to ensure zero failure in harsh environments.

Applications

DC Fast Charging Modules (60kW - 480kW)

On-Board Chargers (OBC)

Power Distribution Units (PDU)

Liquid-cooled Charging Connectors

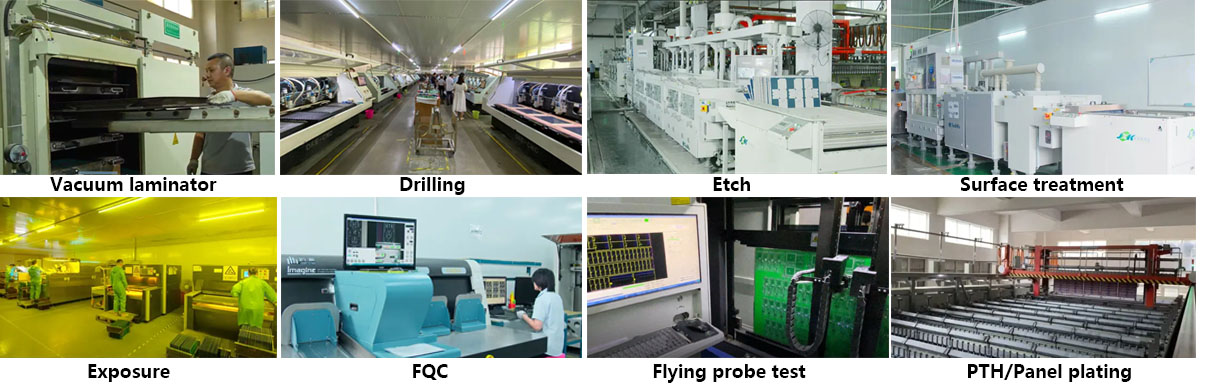

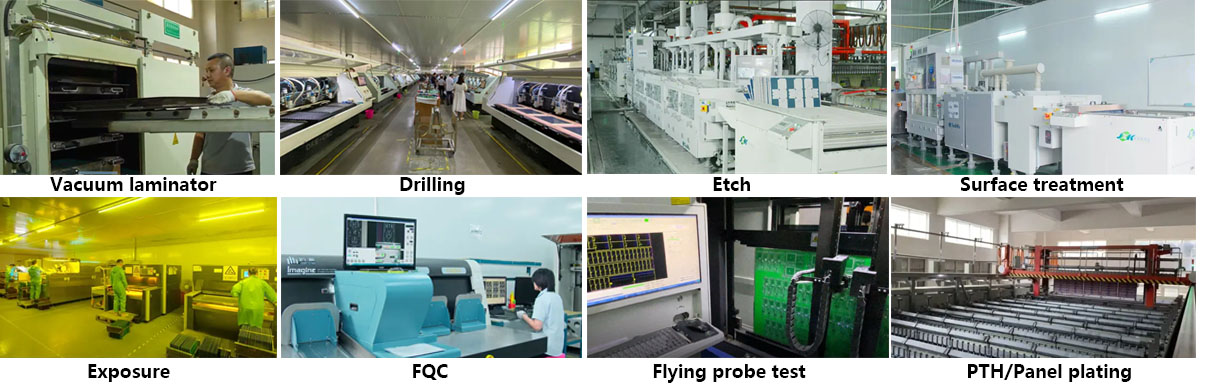

Our Strong Production Capacity

Our Customers Reference

FAQ

Q1: Where are you headquartered?

Foshan, China(south of China)

Q2: Are you a trading company or manufacturer?

We are a PCB&PCBA manufacturer with 10+ years experiences.

Q3: What countries do you export your products to?

We export our PCB/PCBA solutions to more than 30 countries, including USA,EUROPE,MIDDLE EAST,AUSTRALIA,AGENTINA,BRAZIL and so on.

Q4: What is your lead time/production time?

1-3 weeks

Q5:Do you offer free samples?

Free in 3 new models

Q6:What's your MOQ?

100pcs

Q7:How's your quality control?

We have 100% unit inspection, process:

Strictly Select Suppliers->IQC->IPQC->ICT->AOI TEST->X-ray Test->Function Test

1.Thermal Performance Testing

2.Electrical Testing(Hi-Pot Test / Dielectric Withstanding Voltage, Dielectric Breakdown Voltage, Continuity & Short Test)

3.Mechanical Testing

4.Surface & Process Testing

Q8:How's your production capacity?

50,000㎡/month

Our Company Profile

Guoli Optoelectronics has more than 10 years experiences in PCB, PCBA design and manufacturing, copper base PCB application, we have strong engineers team for software and hardware development, and with 50+ patents in PCB products. We have 4 manufacturing bases and 600+ staffs, strong production capacity and fast response to make sure your project run efficiently. We have thousands of successful customers and cases globally, and serving the brands in industry worldwide.

We have complete quality control system and management system to keep our product quality, including UL, Rohs, ISO9001, ISO14001 and IATF16949.

Our Advantages

1. Save Time and Costs: GUOLI provides PCB design, sourcing, assembly, testing, and after-sales services, reducing communication and delivery time with different suppliers, improving efficiency, and lowering costs.

2. Reduce Errors: PCB design and assembly defects can cause project delays. GUOLI's one-stop PCBA service reduces various errors, including design, sourcing, and assembly mistakes, thereby improving quality control.

3. Strong Technical Team: GUOLI's one-stop PCBA service is typically equipped with an experienced technical team to help customers solve various technical problems and ensure timely project completion.

4. Unified Warranty and After-Sales Service: GUOLI's one-stop PCBA service provides unified warranty and after-sales service, helping to build long-term partnerships and achieve mutual benefit.

5. Customized Services: GUOLI's one-stop PCBA service can provide more personalized services based on customers' specific needs and requirements, and develop suitable circuit boards and system components.

| Layer | 2L-20L |

| Base Material | Copper |

| Specification | PCB customized size |

| Delivery | 7-14 Days |

| Certification | UL(CUL), IS09001&IS014001, IATF16949, REACH, RoHS, |

| Application | EV charging station |

| Transport Package | Vacuum Package and Foam Protected |

| Copper thickness | 2-40oz |

| Surface treatment | OSP, HASL, Tin, Immersion Gold (Au), Immersion Silver (Ag), ENIG, ENPIG |

| Min. Trace/Space | 3.5mil / 3.5mil |

| Dielectric Layer Thermal Conductivity(w/m.k) | 380.0W-400.0W, Breakdown Voltage: 2KV - 6KV |

| Current Loading | 200A+ single line capacity |

Our Reliable Material Suppliers

Our Product Features

1.Thermal Management. Afford IGBT overheating at 400V/800V.Superior Heat Dissipation.Direct thermal path from components to the copper block, reducing junction temperature by 30%.

2.Space Constraint. Integrate power and control logic on a single board

3.Reliability. Work well under extreme outdoor temperatures

4.High Current Handling: Heavy copper combined with embedded blocks to minimize losses.

5.Space Saving. Eliminates the need for bulky external busbars and heavy heatsinks.

6.Extreme Durability: Tested for thermal cycles to ensure zero failure in harsh environments.

Applications

DC Fast Charging Modules (60kW - 480kW)

On-Board Chargers (OBC)

Power Distribution Units (PDU)

Liquid-cooled Charging Connectors

Our Strong Production Capacity

Our Customers Reference

FAQ

Q1: Where are you headquartered?

Foshan, China(south of China)

Q2: Are you a trading company or manufacturer?

We are a PCB&PCBA manufacturer with 10+ years experiences.

Q3: What countries do you export your products to?

We export our PCB/PCBA solutions to more than 30 countries, including USA,EUROPE,MIDDLE EAST,AUSTRALIA,AGENTINA,BRAZIL and so on.

Q4: What is your lead time/production time?

1-3 weeks

Q5:Do you offer free samples?

Free in 3 new models

Q6:What's your MOQ?

100pcs

Q7:How's your quality control?

We have 100% unit inspection, process:

Strictly Select Suppliers->IQC->IPQC->ICT->AOI TEST->X-ray Test->Function Test

1.Thermal Performance Testing

2.Electrical Testing(Hi-Pot Test / Dielectric Withstanding Voltage, Dielectric Breakdown Voltage, Continuity & Short Test)

3.Mechanical Testing

4.Surface & Process Testing

Q8:How's your production capacity?

50,000㎡/month

Our Company Profile

Guoli Optoelectronics has more than 10 years experiences in PCB, PCBA design and manufacturing, copper base PCB application, we have strong engineers team for software and hardware development, and with 50+ patents in PCB products. We have 4 manufacturing bases and 600+ staffs, strong production capacity and fast response to make sure your project run efficiently. We have thousands of successful customers and cases globally, and serving the brands in industry worldwide.

We have complete quality control system and management system to keep our product quality, including UL, Rohs, ISO9001, ISO14001 and IATF16949.

Our Advantages

1. Save Time and Costs: GUOLI provides PCB design, sourcing, assembly, testing, and after-sales services, reducing communication and delivery time with different suppliers, improving efficiency, and lowering costs.

2. Reduce Errors: PCB design and assembly defects can cause project delays. GUOLI's one-stop PCBA service reduces various errors, including design, sourcing, and assembly mistakes, thereby improving quality control.

3. Strong Technical Team: GUOLI's one-stop PCBA service is typically equipped with an experienced technical team to help customers solve various technical problems and ensure timely project completion.

4. Unified Warranty and After-Sales Service: GUOLI's one-stop PCBA service provides unified warranty and after-sales service, helping to build long-term partnerships and achieve mutual benefit.

5. Customized Services: GUOLI's one-stop PCBA service can provide more personalized services based on customers' specific needs and requirements, and develop suitable circuit boards and system components.