close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

| Layer | 1/2/4L |

| Base Material | Copper |

| Specification | PCB customized size |

| Delivery | 7-14 Days |

| Certification | UL(CUL), IS09001&IS014001, IATF16949, REACH, RoHS, |

| Application | Automotive Headlights, Secondary Power Supplies, Optoelectronics, Stage Lighting, Outdoor Lighting, Medical Equipment, UV Curing |

| Transport Package | Vacuum Package and Foam Protected |

| Surface treatment | OSP / Immersion Nickel Gold / Immersion Nickel Palladium Gold / Immersion Tin / HASL |

| Product Thickness min./max. | 0.6/3.2 |

Minimum Dielectric Layer Thickness | 38μm |

Maximum Outer Layer Copper Thickness | 15oz |

| Minimum Outer Layer Line Width/Gap | 0.1/0.1mm |

| Minimum Mechanical Hole Diameter | 0.6mm |

| Minimum Solder Mask Ring Width | 0.05mm |

| Minimum Solder Mask Window | 0.025mm |

| Minimum Pad to Window Tolerance | 0.05mm |

| Minimum Hole to Window Tolerance | 0.05mm |

| Minimum Milling Depth Tolerance | 0.035mm |

| Hole to Pad Tolerance | 0.035mm |

| Hole to Hole Tolerance | 0.035mm |

| Dielectric Layer Thermal Conductivity(w/m.k) | 1.0W-400.0W |

Multilayer copper-based PCBs represent the pinnacle of high-performance metal-core PCBs (MCPCBs). Compared to common aluminum-based or ordinary FR4 boards, they specifically address the conflict between heat dissipation and electrical performance in high-power, highly integrated devices through the combination of multiple conductive layers and a high thermal conductivity copper substrate.

Our Reliable Material Suppliers

Our Product Features

Professional in High thermal conductivity, High voltage resistance, High current.

1.Extremely High Thermal Conductivity. Can reach to 400W

2.Thermoelectric Separation Process

3.Multilayer Density for 4 layers

4.High Mechanical Strength and Stability

5.Superior Heat Dissipation Capacity. Due to high heat dissipation efficiency, the operating temperature of components can be reduced by 10°C-20°C

6.Higher Current Carrying Capacity(using copper foil thicker than 3 oz for inner or outer layers)

7.Excellent Electromagnetic Shielding (EMI Shielding)

8.Miniaturization

9.Excellent Vibration Resistance and Corrosion Resistance

10.Quality Control: 100% AOI testing, flying probe testing, E-test.

11.Fast Response: Inquiry response within 2 hours, global logistics support.

Applications

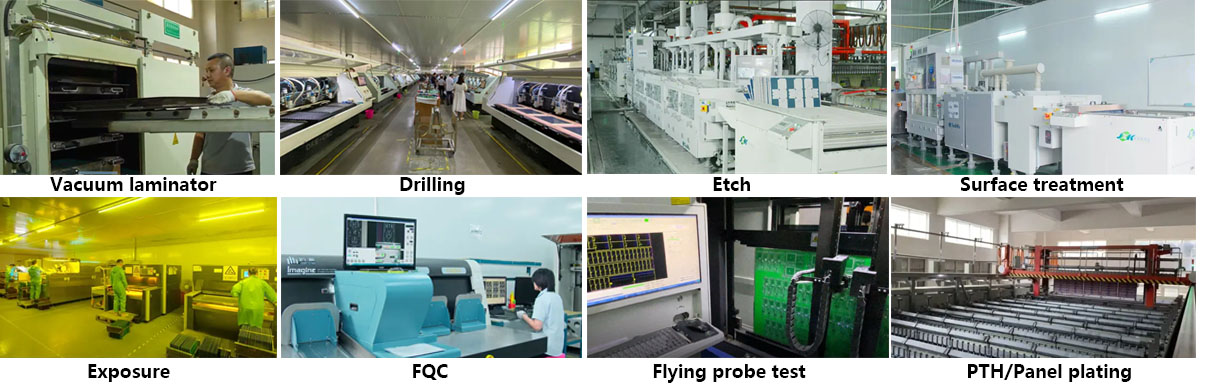

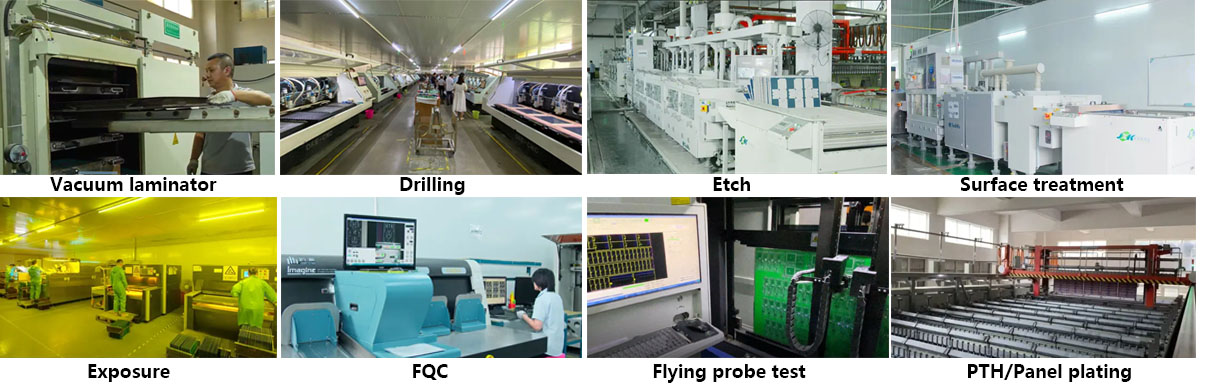

Our Strong Production Capacity

Our Customers Reference

FAQ

Q1: Where are you headquartered?

Foshan, China(south of China)

Q2: Are you a trading company or manufacturer?

We are a PCB&PCBA manufacturer with 10+ years experiences.

Q3: What countries do you export your products to?

We export our PCB/PCBA solutions to more than 30 countries, including USA,EUROPE,MIDDLE EAST,AUSTRALIA,AGENTINA,BRAZIL and so on.

Q4: What is your lead time/production time?

1-3 weeks

Q5:Do you offer free samples?

Free in 3 new models

Q6:What's your MOQ?

100pcs

Q7:How's your quality control?

We have 100% unit inspection, process:

Strictly Select Suppliers->IQC->IPQC->ICT->AOI TEST->X-ray Test->Function Test

1.Thermal Performance Testing

2.Electrical Testing(Hi-Pot Test / Dielectric Withstanding Voltage, Dielectric Breakdown Voltage, Continuity & Short Test)

3.Mechanical Testing

4.Surface & Process Testing

Our Company Profile

Guoli Optoelectronics has more than 10 years experiences in PCB, PCBA design and manufacturing, copper base PCB application, we have strong engineers team for software and hardware development, and with 50+ patents in PCB products. We have 4 manufacturing bases and 600+ staffs, strong production capacity and fast response to make sure your project run efficiently. We have thousands of successful customers and cases globally, and serving the brands in industry worldwide.

We have complete quality control system and management system to keep our product quality, including UL, Rohs, ISO9001, ISO14001 and IATF16949.

Our Advantages

1. Save Time and Costs: GUOLI provides PCB design, sourcing, assembly, testing, and after-sales services, reducing communication and delivery time with different suppliers, improving efficiency, and lowering costs.

2. Reduce Errors: PCB design and assembly defects can cause project delays. GUOLI's one-stop PCBA service reduces various errors, including design, sourcing, and assembly mistakes, thereby improving quality control.

3. Strong Technical Team: GUOLI's one-stop PCBA service is typically equipped with an experienced technical team to help customers solve various technical problems and ensure timely project completion.

4. Unified Warranty and After-Sales Service: GUOLI's one-stop PCBA service provides unified warranty and after-sales service, helping to build long-term partnerships and achieve mutual benefit.

5. Customized Services: GUOLI's one-stop PCBA service can provide more personalized services based on customers' specific needs and requirements, and develop suitable circuit boards and system components.

| Layer | 1/2/4L |

| Base Material | Copper |

| Specification | PCB customized size |

| Delivery | 7-14 Days |

| Certification | UL(CUL), IS09001&IS014001, IATF16949, REACH, RoHS, |

| Application | Automotive Headlights, Secondary Power Supplies, Optoelectronics, Stage Lighting, Outdoor Lighting, Medical Equipment, UV Curing |

| Transport Package | Vacuum Package and Foam Protected |

| Surface treatment | OSP / Immersion Nickel Gold / Immersion Nickel Palladium Gold / Immersion Tin / HASL |

| Product Thickness min./max. | 0.6/3.2 |

Minimum Dielectric Layer Thickness | 38μm |

Maximum Outer Layer Copper Thickness | 15oz |

| Minimum Outer Layer Line Width/Gap | 0.1/0.1mm |

| Minimum Mechanical Hole Diameter | 0.6mm |

| Minimum Solder Mask Ring Width | 0.05mm |

| Minimum Solder Mask Window | 0.025mm |

| Minimum Pad to Window Tolerance | 0.05mm |

| Minimum Hole to Window Tolerance | 0.05mm |

| Minimum Milling Depth Tolerance | 0.035mm |

| Hole to Pad Tolerance | 0.035mm |

| Hole to Hole Tolerance | 0.035mm |

| Dielectric Layer Thermal Conductivity(w/m.k) | 1.0W-400.0W |

Multilayer copper-based PCBs represent the pinnacle of high-performance metal-core PCBs (MCPCBs). Compared to common aluminum-based or ordinary FR4 boards, they specifically address the conflict between heat dissipation and electrical performance in high-power, highly integrated devices through the combination of multiple conductive layers and a high thermal conductivity copper substrate.

Our Reliable Material Suppliers

Our Product Features

Professional in High thermal conductivity, High voltage resistance, High current.

1.Extremely High Thermal Conductivity. Can reach to 400W

2.Thermoelectric Separation Process

3.Multilayer Density for 4 layers

4.High Mechanical Strength and Stability

5.Superior Heat Dissipation Capacity. Due to high heat dissipation efficiency, the operating temperature of components can be reduced by 10°C-20°C

6.Higher Current Carrying Capacity(using copper foil thicker than 3 oz for inner or outer layers)

7.Excellent Electromagnetic Shielding (EMI Shielding)

8.Miniaturization

9.Excellent Vibration Resistance and Corrosion Resistance

10.Quality Control: 100% AOI testing, flying probe testing, E-test.

11.Fast Response: Inquiry response within 2 hours, global logistics support.

Applications

Our Strong Production Capacity

Our Customers Reference

FAQ

Q1: Where are you headquartered?

Foshan, China(south of China)

Q2: Are you a trading company or manufacturer?

We are a PCB&PCBA manufacturer with 10+ years experiences.

Q3: What countries do you export your products to?

We export our PCB/PCBA solutions to more than 30 countries, including USA,EUROPE,MIDDLE EAST,AUSTRALIA,AGENTINA,BRAZIL and so on.

Q4: What is your lead time/production time?

1-3 weeks

Q5:Do you offer free samples?

Free in 3 new models

Q6:What's your MOQ?

100pcs

Q7:How's your quality control?

We have 100% unit inspection, process:

Strictly Select Suppliers->IQC->IPQC->ICT->AOI TEST->X-ray Test->Function Test

1.Thermal Performance Testing

2.Electrical Testing(Hi-Pot Test / Dielectric Withstanding Voltage, Dielectric Breakdown Voltage, Continuity & Short Test)

3.Mechanical Testing

4.Surface & Process Testing

Our Company Profile

Guoli Optoelectronics has more than 10 years experiences in PCB, PCBA design and manufacturing, copper base PCB application, we have strong engineers team for software and hardware development, and with 50+ patents in PCB products. We have 4 manufacturing bases and 600+ staffs, strong production capacity and fast response to make sure your project run efficiently. We have thousands of successful customers and cases globally, and serving the brands in industry worldwide.

We have complete quality control system and management system to keep our product quality, including UL, Rohs, ISO9001, ISO14001 and IATF16949.

Our Advantages

1. Save Time and Costs: GUOLI provides PCB design, sourcing, assembly, testing, and after-sales services, reducing communication and delivery time with different suppliers, improving efficiency, and lowering costs.

2. Reduce Errors: PCB design and assembly defects can cause project delays. GUOLI's one-stop PCBA service reduces various errors, including design, sourcing, and assembly mistakes, thereby improving quality control.

3. Strong Technical Team: GUOLI's one-stop PCBA service is typically equipped with an experienced technical team to help customers solve various technical problems and ensure timely project completion.

4. Unified Warranty and After-Sales Service: GUOLI's one-stop PCBA service provides unified warranty and after-sales service, helping to build long-term partnerships and achieve mutual benefit.

5. Customized Services: GUOLI's one-stop PCBA service can provide more personalized services based on customers' specific needs and requirements, and develop suitable circuit boards and system components.